Oxygen is one of the most common gases and it is available in the atmosphere we breathe. In the gaseous state it is colourless, odourless and tasteless, so a possible concentration increase in the air cannot be easily detected. The risks deriving from a high accumulation of oxygen in the air mainly concern breathing difficulties causing, in the most serious cases, lung damage and dangerous explosions because oxygen is a strong oxidant.

The lack of oxygen is equally dangerous, generating asphyxiating atmospheres which statistically generate the greatest number of accidents at work due to gases.

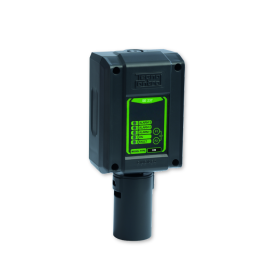

To ensure the safety of workers and to preserve the healthiness of environments where higher or lower than normal oxygen concentrations may occur, oxygen detectors prove to be essential, among them the sensitive, reliable, precise SE237EO and TS282E0 by Tecnocontrol, signed by Giugiaro and thus having a unique and innovative design.

The detectors have top-notch performance: a 4-20mA output and 3 alarm relays (model SE237EO) in addition to the fault, potential free, freely programmable if in positive or negative logic or if normally open or normally closed.

The alarm thresholds can be selected among the combinations available by setting the dip switches on the sensor, or via the current output, they can be connected to a gas powered plant and thus have a better management control of its operation.

The luminous signals promptly indicate the operating status and are particularly useful during the periodic check and calibration automatic process.

When the cartridge is exhausted, it can be easily replaced only by removing the bayonet movement sensor holder.

The TS282EO oxygen gas detectors have 4-20mA linear output while the SE237EO model also has intervention thresholds that can be set via dip-switches arranged on the electronics, as well as the TS282EO model, with a linear proportional output 4 ÷ 20 mA. Both are equipped with an electrochemical cell with a measuring range of 0 ÷ 25% of the volume and an operating limit of 30% Vol.

The other technical features are as follows: power supply 12 ÷ 24Vdc (-10 / + 15%) 2W, an operating pressure of ± 10% compared to the atmosphere, operating temperature -20 ÷ + 40 ° C and an operating humidity of 15 ÷ 90% RH not condensed.

SE237EO and TS 282EO have a IP65 protection housing (238x106x75 mm) containing the microprocessor electronic circuit and the Ø 48mm x 80mm dimension cylindrical sensor holder and are particularly suitable for the industrial and chemical fields applications.

The sensor holder situated in the lower part of the housing, is in fact made of a particular IP65 maze (labyrinth) so that it can block any solid or liquid substance before reaching the sensitive element, with consequent operation compromising. It accommodates the replaceable sensor cartridge cod. ZSEO1 / IP for easy replacement when exhausted.

The connection is simplified thanks to removable plug-in terminals, the output signal is 4 ÷ 20 mA which can be taken from the "S" terminal and must be compatible with all gas control units of the "CE" series which are also equipped with innovative features and able to meet the needs of users and installers.

On the outside of the SE237EO case there are 5 LEDs that represent the three alarm thresholds, the network presence and the fault (Fault) including malfunctions related to a faulty or disconnected sensor or full scale or expired sensor.

On the cover of TS282EO, the 3 LEDs indicating the operating conditions establish the optical alarm signal (Red "ALARM" LED), normal operation (Green LED "ON" and the faulty or disconnected sensor or at full scale or expired sensor (Yellow LED "FAULT")

Also on the outside of the case, there are buttons to be used to enter the code for "zero" maintenance operations in clean air and sensor calibration, operations that the device performs automatically in total autonomy.